Custom RC Blimp Envelopes & blown shapes – Premium TPU, Low Helium Loss

Worlwide delivery - to more than 90 countries

Custom RC Blimp Envelopes: Precision Crafted for Your Vision

RC Zeppelin specializes in custom envelopes for blimps and LTA (Lighter-Than-Air) shapes, delivering high-performance solutions since 2003. These envelopes use premium UK-imported TPU (polyurethane film) in 100, 125, and 150-micron thicknesses, ensuring durability and minimal helium loss of just 0.5-0.7% per day.

Why Choose Custom Envelopes?

Custom blimp envelopes outperform stock options by matching exact project needs, from size to shape. Symmetrical or asymmetrical designs up to 15 meters (or larger) support diverse applications like research, advertising, professional needs and hobby RC flying. TPU's high abrasion resistance, tear strength, and airtightness make it ideal for indoor and outdoor use, resisting hydrolysis, acids, oils, and UV degradation.

Helium permeability is critical for LTA efficiency; RC Zeppelin's double-welding technology achieves industry-leading low rates, far below averages of 3L/m²/day in standard fabrics. This minimizes refills, cuts costs, and extends flight times—essential for universities, startups, and professionals.

Materials and Construction Excellence

We source top-grade TPU for unbeatable strength and gas retention, with options like Tedlar or Mylar on request. At 100-150 microns, these films balance lightness and robustness, perfect for RC blimps carrying payloads like cameras or sensors. Production involves precise 3D modeling, paper prototypes for validation, and ultrasonic welding for seamless, pinhole-free envelopes. Aging tests show TPU maintains low permeability (0.2-1 L/m²·day·atm) even after months, outperforming alternatives like PVC-coated nylon. Ballonets for pressure control are available, ensuring stable flight in varying conditions.

Design and production process

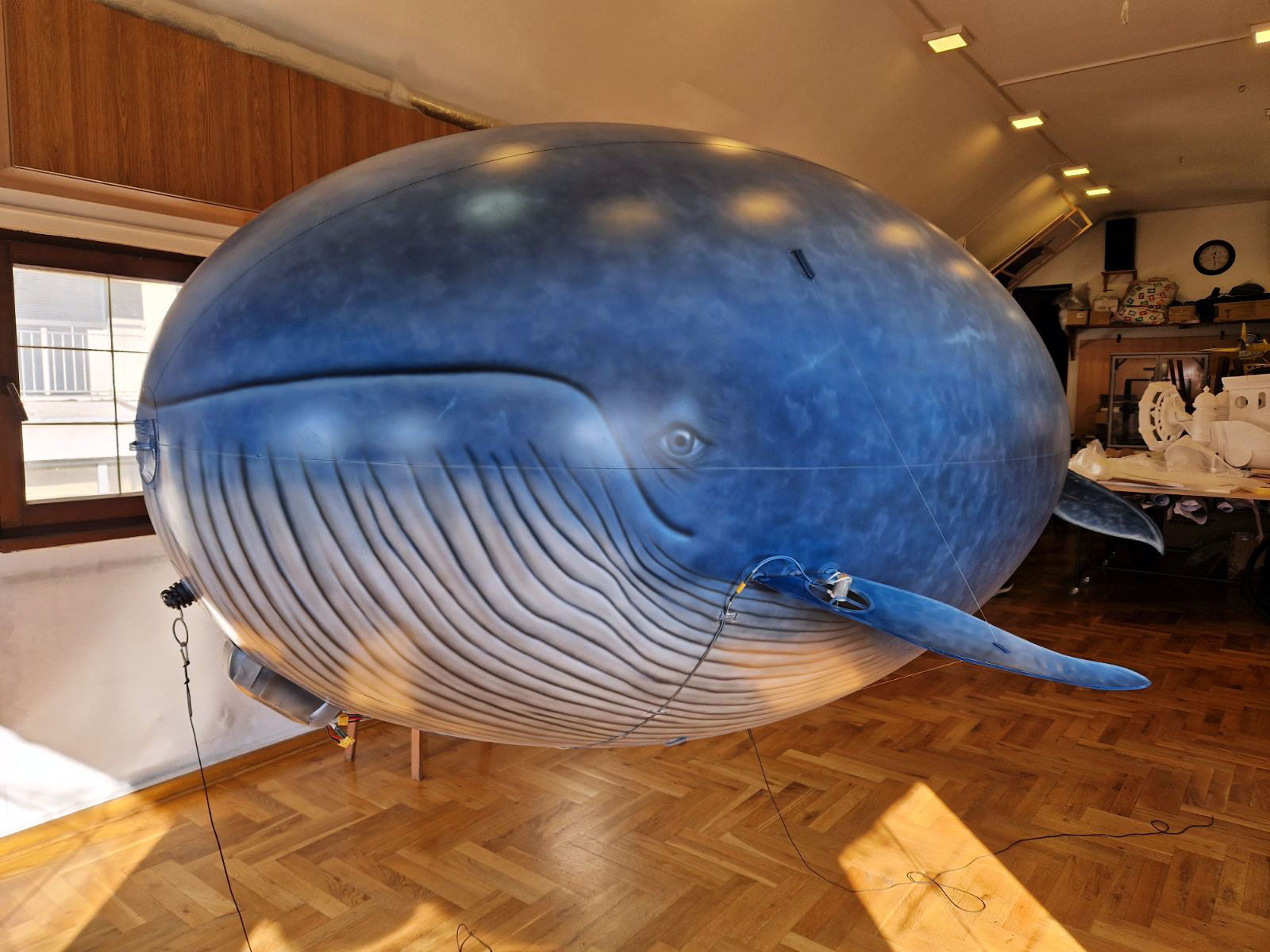

Start by submitting your 3D model, sketch, or concept specs (size, volume, shape, payload). The team refines it into a production-ready 3D file, optimizing for aerodynamics (if needed), lift (via helium volume calculations), and stability—symmetrical for RC blimps or asymmetrical for custom shapes like whales. A paper prototype is crafted next to validate real-world volume, fit, and proportions before committing to materials. The 3D model generates large-format 2D patterns (gores/panels), printed with less than 0.5% error tolerance. Panels are precisely cut from TPU sheets using heat tools (e.g., soldering irons) to seal edges and prevent tears. Panels align on custom jigs/tools for accuracy. Ultrasonic welding creates airtight seams, eliminating pinholes—key to the guaranteed less than 1% daily gas loss. Ballonets, fins, or valves integrate here for pressure control and flight performance. Post-assembly, the envelope inflates with air/helium for leak tests, permeability checks, and shape verification. Rigorous inspections ensure specs match; any issues trigger re-welding. Final packaging includes inflation guides for easy setup.

Key Technical Specs

The technical characteristics directly depend on the blown form and other aerodynamic, electric, electronic, etc. which is done for you but the basic specifications below are similar for all blown shapes with or without RC.

- Envelope: Volumes from 0.7m³ (1.5m indoor RC) to 15m+; abrasion/UV-resistant TPU outperforms PVC/nylon.

- Lift: 100-200g payload for small models; scales with helium volume (e.g., 1.5m³ lifts ~200g).

- Assembly: Airtight seams via ultrasonic welding; optional ballonets for pressure, valves for inflation.

- RC Systems: Futaba/Kavan-compatible; 2.4GHz multi-channel for throttle, vectors, ballast..

- Durability: Repair kits with 0.4m² TPU film; flight times 30-40min on 1500mAh LiPo or depending on size/volume

Applications for Custom Envelopes

Research/Prototyping: Aerostats or free flying shapes/Blimps for universities testing sensors, surveillance, or environmental monitoring. Events: Eye-catching shapes like whales, aliens, cylinders or asymmetrical designs for promotions and airshows Advertising: Branded envelopes with printed logos via our proprietary TPU printing tech—no quality compromise. RC Hobbyists: Tailored indoor/outdoor blimps for freestyle flying or racing, with volumes from 0.7m³ upward.

Order now

The first step is to contact us with your custom blown shape or other design at the email below.

After the completed 3D design and acceptance by the client, we form the price and the production deadline.

Mobile, WhatsApp, Viber:

+381 64 12 13 546, +381 64 56 37 679

rczeppelin@gmail.com or rczeppelin@protonmail.com

Delivered in a custom humidity protection plywood box

Aero Drum LTD Company Origins

Founded by Aero Drum Ltd, RC-Zeppelin.com began serial production of RC blimps in 1999, drawing on decades of lighter-than-air expertise to create the smallest ready-to-fly models like the 1.5m indoor RC blimp. From humble beginnings in Europe, the site evolved into a global hub for hobbyists, advertisers, and professionals seeking helium-filled zeppelins under 12m, filling a niche left by larger rigid airships of the early 20th century. By 2026, it powers sales through rcblimpsforsale.com, honoring Zeppelin heritage while innovating for modern RC flying.

Warning: Flying outdoor RC blimps requires advanced prior knowledge of RC piloting as well as all necessary public flight licenses.